SL6-Hx Here to be seen in the milling dialogue HPGL CI command.is used. SL2M3 transposes this into drill-milling, means the tool moves in a helical path with the 'feed X,Y' into the PCB. The feed and the steps (Number of helical paths to the drilling depth) can be entered. The feed Z arises from the fact. At the end of the Helical path to drill deep a complete circular path is milling without Z-feed.

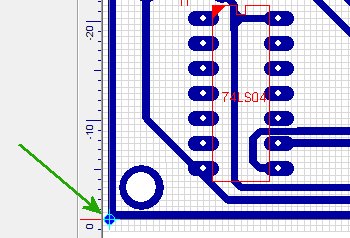

Example in the picture:

Helix with 2 steps (left) and Helix with 5 steps (right))